Slot die coating technology allows for a precise deposition of a variety of liquids or pastes onto different substrates such as glass, steel, or plastic. This coating technology allows for a precise dispensing of fluid at a controlled rate while the coating die is accurately moved relative to the substrate.

We designed and built our own laboratory scale slot die coater to investigate the processing behavior of ceramic pastes and pastes for Li-ion batteries as well as for other applications in printed electronics. The main advantages of this laboratory scale slot die coater are the die itself and the 2D-Laser triangulation device, which allows for an accurate detection of the coating layer profile, i.e. the film thickness. Using easy-to-build and exchangeable cartridges enables a flexible design of the slot die geometry.

- to be implemented soon -

Fig. 1: Layout of our lab scale coater

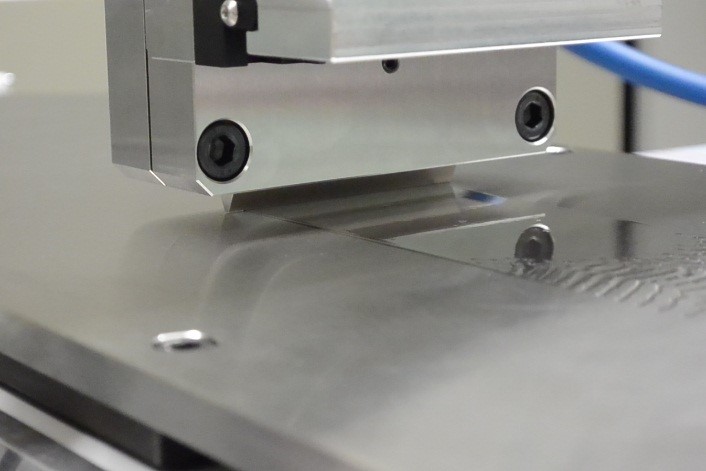

Fig. 2: Working die in detail

Specifications

Slot gap range: 0 – 2.500 µm

Max. working width: 60 mm

Coating speed: 0.1 – 100 mm/s

Max. coating distance: 600 mm

Die – substrate distance: 0 – 25 mm